Three big redesigns unveiled at North American International Auto Show 2017

This year at the Motor City’s premier automotive event, the North American International Auto Show (NAIAS), aside from the usual assortment of concepts and future tech teasers, the big news was focused around the next generation of a group of well-established models from Honda, Toyota and Lexus. Let’s take a look.

2018 Honda Odyssey

Making its world debut in Detroit, Honda’s best-selling minivan gets a complete redesign. Besides its obviously sleeker profile and addition of the “flying wing” front grille also found on siblings like the Civic and Ridgeline, there are a ton of new features. The Magic Slide second row seats can be configured in countless a ways to allow for different seating positions, easy access to the third row and increased storage capacity.

Drivers no longer have to wonder what’s going on behind them — utilizing a camera, CabinWatch shows rear passenger activity on the eight-inch Display Audio screen, and CabinTalk allows two-way communication via the on-board speaker system and rear entertainment system headphones. And parents of messy children and/or pets can breathe easy, because the HondaVac built-in vacuum returns for 2018.

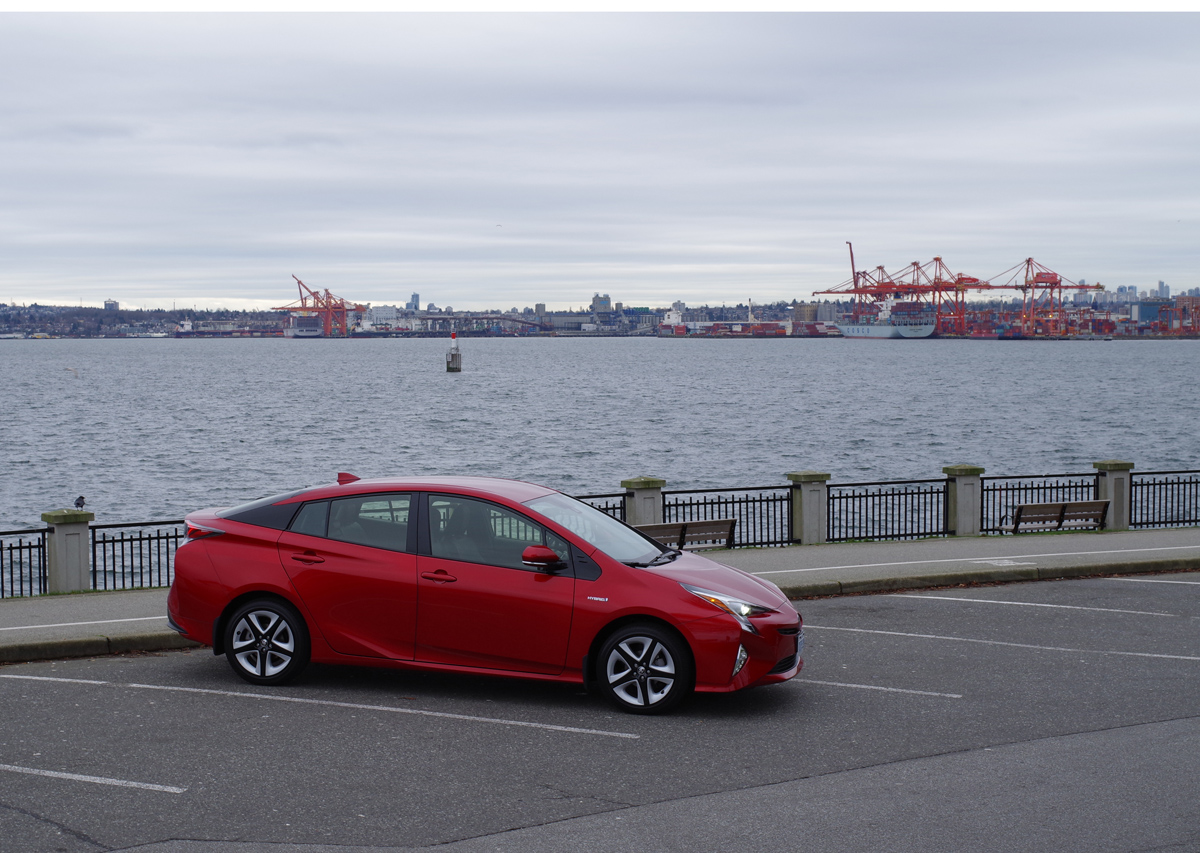

2018 Toyota Camry

Including the latest version that was just revealed in Detroit, there have now been eight generations of the Toyota Camry. And it shows no signs of slowing down. Based upon the Toyota New Global Architecture platform, the family sedan — offered in gasoline or hybrid form — takes on a, dare I say, sporty appearance, expressed through a two-piece grille, stylized front and rear bumpers and lower hood and roofline.

At the top of the five-grade lineup are the SE and XSE, both wearing even more aggressive front and rear fascias, larger wheels, lip spoilers and black accents. Inside, all Camrys are available with “futuristic” equipment such as three interlinked displays consisting of a 10-inch HUD, seven-inch multi-information instrument cluster display and an eight-inch screen responsible for audio, navigation and climate control readouts.

2018 Lexus LS 500

When the Japanese luxury nameplate launched in North America nearly 28 years ago, everything was riding on one vehicle: the LS 400. It set all kinds of benchmarks in terms of comfort, value, quality, etc., and Lexus is hoping to do it all again with the 2018 LS 500. Like the original, this flagship is rear-wheel drive and embodies the latest signature Lexus design language.

Resting under the hood is a powerplant developed using the company’s ties with F1 racing. Perfectly balancing performance and efficiency, a twin-turbo 3.5-litre V6 produces 415 horsepower and 442 lb-ft of torque, tuned to deliver quick acceleration and a throaty yet refined exhaust note. As a first for a premium passenger car, the engine is mated to an advanced electronically controlled 10-speed automatic transmission capable of anticipating driver input.